◆ The buoyancy cable has excellent characteristics such as water resistance, oil resistance, cold resistance, corrosion resistance, UV resistance, abrasion resistance, flame retardancy, bending resistance, etc. It is suitable for fast moving installation occasions. The imported high-quality materials and new improved technology are used to make the cable have smaller outer diameter and lighter weight, which can meet the requirements of more complex working conditions

◆ Bending resistance - optimized cable pitch+special structure design+careful material selection, suitable for high frequency bending occasions

◆ Tensile - flexible wrapping material - non-woven fabric wrapped wire body+Kevlar anti rope filling+Kevlar string weaving, which can effectively buffer the cable from bending back and forth

◆ Special flexible special sheathing material (color can be selected by the customer) is used for the cable, and the sheath will not crack if the bending life is more than 10 million times

◆ the cable has flexibility, abrasion resistance, oil resistance, acid and alkali resistance, tensile strength, excellent waterproof performance and anti-aging performance; The design cable proportion is infinitely close to the proportion of water, and the cable can float on the water

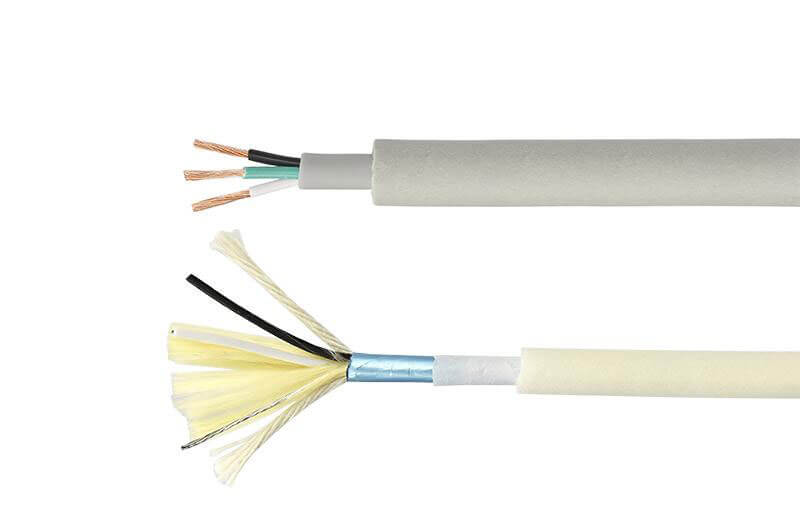

◆ Conductor: multi strand superfine fine twisted oxygen free copper wire, meeting VDE0295CLASS Class 6 standard

◆ Insulation: special NBR PVC mixed/TPE/XLPE/fluoroplastic (optional).

◆ Filled sheath: chemical foaming technology is adopted for PUR/TPE

◆ Tensile - flexible wrapping material - non-woven fabric wrapped wire body+Kevlar anti rope filling+Kevlar string weaving; Kevlar pull ropes of different specifications are selected for filling according to different tensile strength.

◆ Outer sheath: polyurethane (PUR)/TPE/TPV is coated.

◆ Color: black, gray, orange and yellow, and the skin color can be processed according to the customer's requirements

◆ Specific gravity of wire structure: ① Zero buoyancy cable (underwater suspension cable) 0.99 ± 0.03g/MM ³, The specific gravity of the designed cable is infinitely close to that of water, ② the floating force cable is 0.88 ± 0.06G/MM ³, The specific gravity of cable structure is less than that of water, and the cable can float on the water

◆ Rated voltage:

Cable conductor section a ≤ 0.5mm2 300/300v

Cable conductor section ≥ 0.5mm2 a ≤ 150mm2 300/500v

◆ Test voltage: 2500V

◆ Temperature range: - 40 ℃~+80 ℃

◆ Bending radius of buoyancy cable:

Fixed installation: 5 × Cable outer diameter (D)

Mobile installation:

When the stroke is<10m, the bending radius is 7.5 × D

When the stroke is ≥ 10m, the bending radius is 10 × D

◆ Water pressure resistance classification of zero buoyancy cable: longitudinal water pressure resistance strength: 4.5MPa 6.0MPa 10.0MPa

Horizontal water pressure resistance strength: 10.0MPa 70MPa

◆ The maximum load-bearing drag tensile force is ≤ 1000KG, and the waterproof submergence depth can reach 1000m, which can be produced according to the actual use needs

It is used in the energy supply of underwater robot equipment, and is widely used in the power energy supply of marine exploration robots, fishery, energy industry, underwater entertainment, archaeology, scientific research and teaching, unmanned cabled remote control submersible, underwater camera, underwater construction, underwater search and rescue robots, pipeline detection robots, submersible pumps and various underwater electrical equipment; Link from shore to underwater power supply system.

Normally the cables are packed by drum,carton and put on the pallet and other customized packing are available as per international standard.

![]()