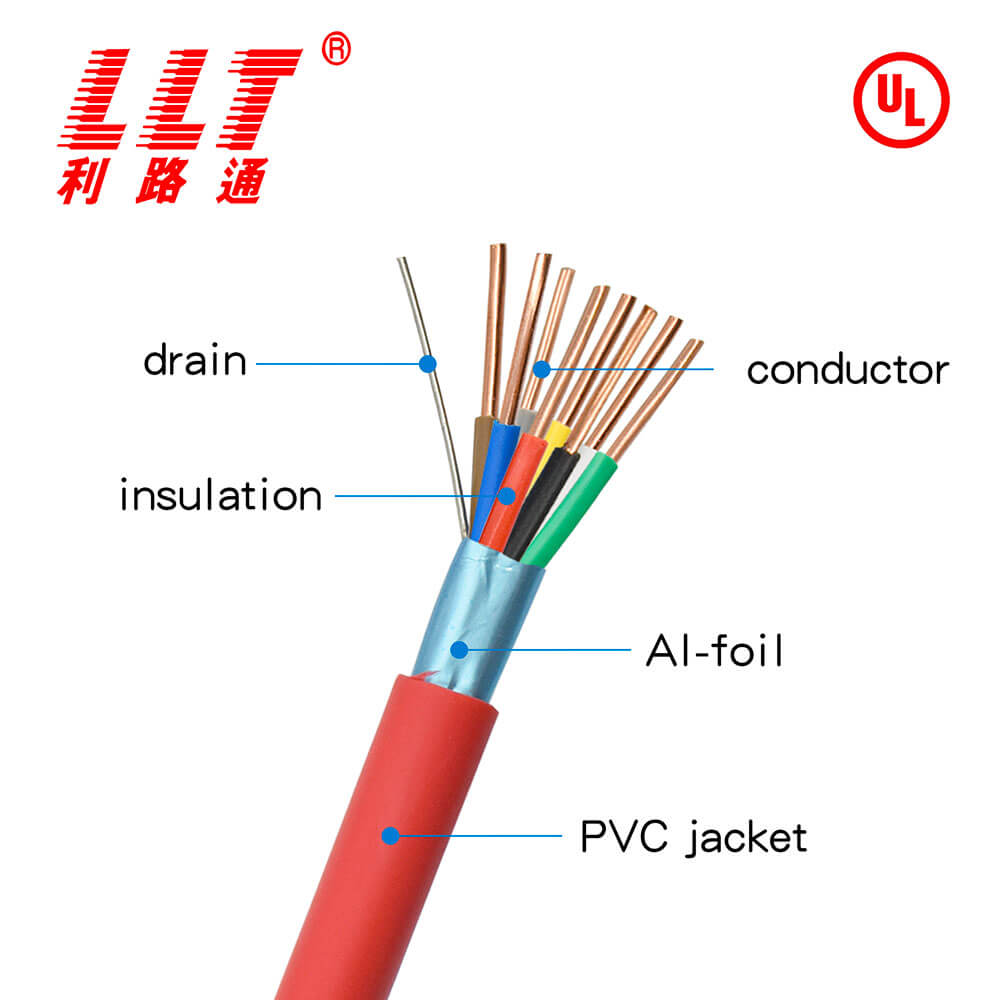

Cable construction:

Conductor:

23 AWG solid Bare Copper

Nom.Dia:0.0226±0.0003"(1/0.574±0.008mm)

Insulation:

Type.polyvinyl chloride

Dia over Insulation:0.0482±0.0040" nom.(1.22±0.10mm)

Drain Wire:1/0.404±0.008mm solid Tinned-Copper

Shield:0.001"(0.025mm)thick Aluminum/Mylar

Color Code:

1.Brn 2.Blue 3.Blk 4.Gry 5.Grn 6.Red 7.Ylw 8.Whi

Jacket:

Type.PVC

jacket color : red or white etc

Dia over Jacket:0.2134±0.0118"(5.4±0.3mm)

Cable Marking:

Fire Alarm Cable (UL) E....... FPL 105℃ 8C/23AWG LLT date

Electrical Properties:

- Temperature Rating:-20℃~+105℃

- Operating Voltage:300 Volts max

- Withstand voltage test :DC: 2500V / 2S, no breakdown

- Minimum insulation resistance :100 MΩ/KFT at15.6℃

- Maximum resistance:73.2 0hms/KM at 20℃

Standard:

- All these cables comply to:

- Application of insulation :UL 1581

- Inner Conductor Diameter:UL 1581

- Insulation Type :UL1581

- Flame Propagation(single Insulation):UL2556

- Flame Propagation(Multiple cables) :UL1685 or IEEE 1202

- Sheath :UL 1581

Cross Section:

All these cables comply to:

Application of insulation :UL 1581

Inner Conductor Diameter:UL 1581

Insulation Type :UL1581

Flame Propagation(single Insulation):UL2556

Flame Propagation(Multiple cables) :UL1685 or IEEE 1202

Sheath :UL 1581

Applications:

Fire-fighting cables are mainly used for emergency lighting, fire observation, signal sensing system, blower system, communication call system, control equipment system, fire pump and fire alarm system circuit cables, etc.

For example: ★ Office ★ School ★ Airport ★ Underground and tunnel ★ Railway station ★ Computer center ★ Alarm system ★ Traffic control system ★ Fire protection system

Packaging information

Normally the cables are packed by drum,carton and put on the pallet and other customized packing are available as per international standard.

Factory information

- Super production capacity-more than 100 sets of automated production equipment, 24-hour production system, daily production capacity of 1,000,000 meters of cables

- Strict quality inspection procedures-material inspection before production, index inspection during production, general quality inspection after production, packaging inspection

- Complete certificate guarantee-IS09001 certification, IS014001 certification, CCC certification, CE certification, UL certification, LPCB certification, VDE certification, etc., so you can purchase with confidence

- Efficient packaging and transportation-machineized packaging, fast and clean. Port city, direct air and sea transportation, fast delivery

- 7*24 hours after-sales service-professionals provide you with services and consultations around the clock

- We can also provide OEM and ODM services

![]()